Fagor LA-35

The Fagor LA-35 TP2 washer comes with:-

- Capacity

- 10:1 – 35kg

- 9:1 – 39kg

- 7″ Touch screen control

- Intelligent weighing system

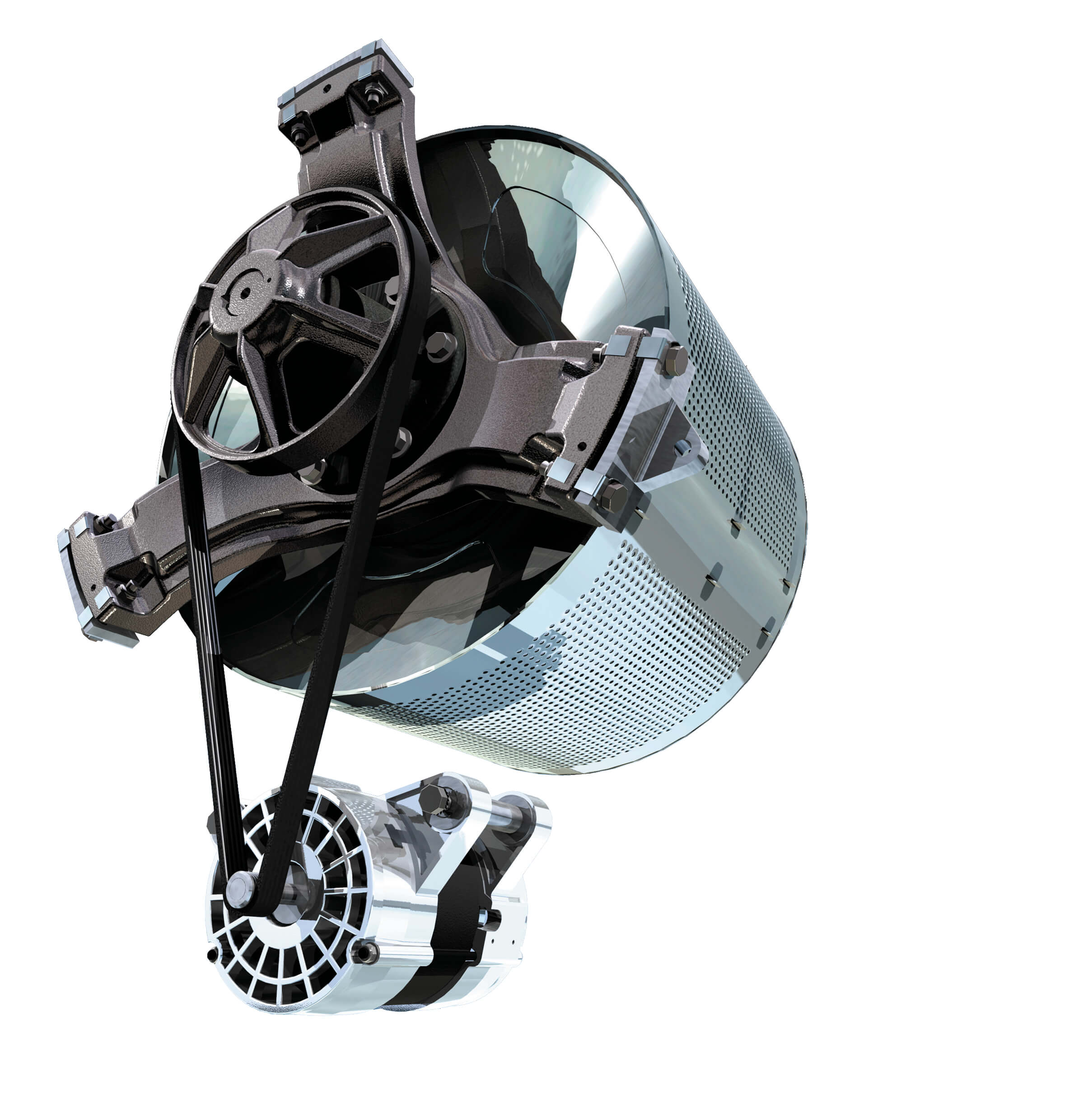

High extract – 450G - Suspended wash barrel

- Three water inlets (Hot, Cold and Aux)

- Wet cleaning ready

- Four compartment manual soap dispenser

- Eight signals for liquid injection. Expandable to 14

- Ozone ready

- Advanced out of balance control

- Optimized soft touch drum design

- 2 years labour warranty

- 2 years parts warranty

- 5 years total, parts bearings, seals, main frame

- Made in Europe

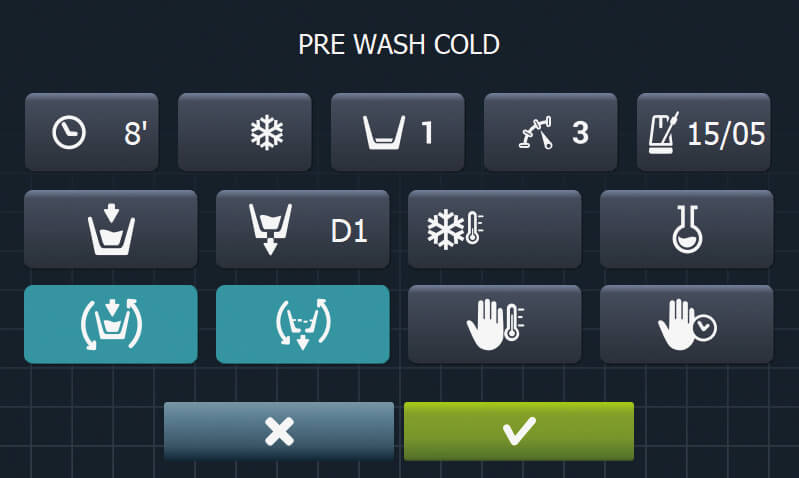

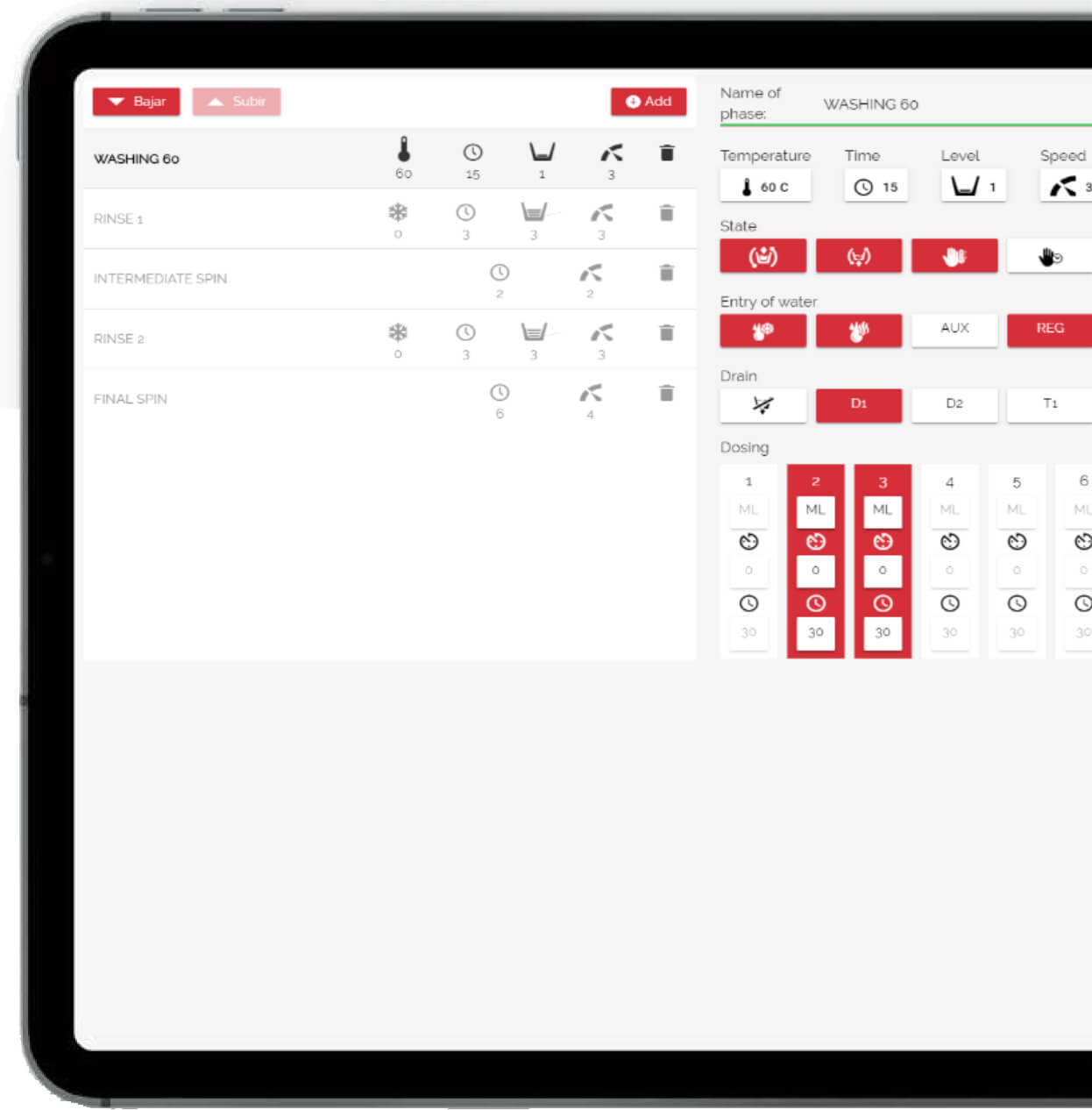

Touch Plus Control

The new Touch Plus Control offers great versatility to the user thanks to its numerous functions: easy programming, 7-inch touch screen in full colour, 37 available languages, USB port for updates and the same control system for OPL washers (for industrial use) and coin washers.

Programable

All our washing machines are equipped with a versatile and easy-to-use touch screen programming system with 26 pre-set programs. These programs can be modified during operation. What is more, you can create, export and import any of the new programs by USB or remote connection.

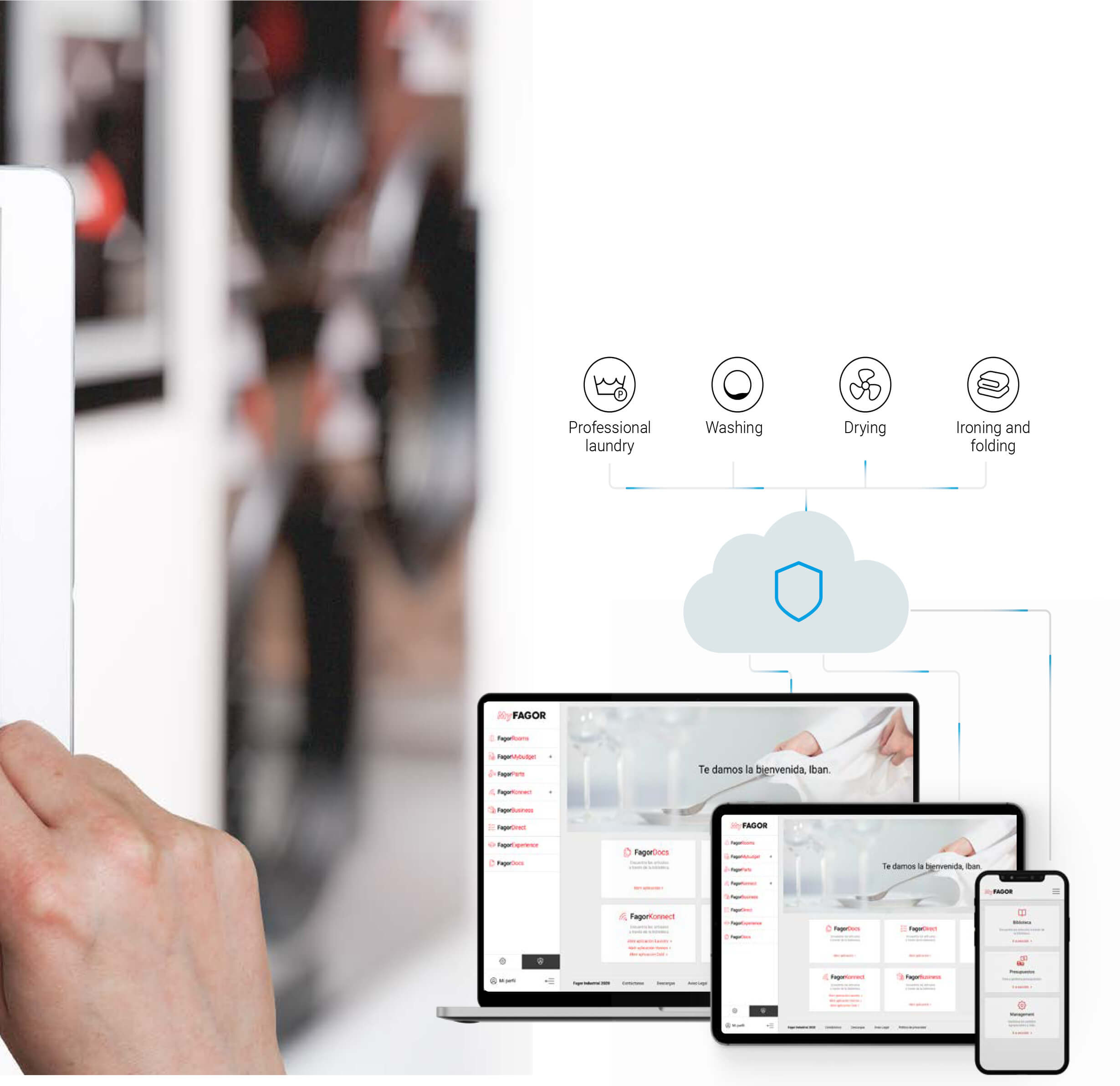

Connectivity

FagorKonnect is our new IOT solution for Connected Laundry. A cloud-based multiple platform and flexible application which lets you manage your laundry from your pocket. However many machines you have, this solution gives you various practical options. Check the state of your machines to know whether they are in standby, in operation, offline, reserved or if they are showing any error. You can also see the location of the different devices. For the Technical Service, FagorKonnect is the tool to anticipate possible problems, detect and resolve them, often remotely.

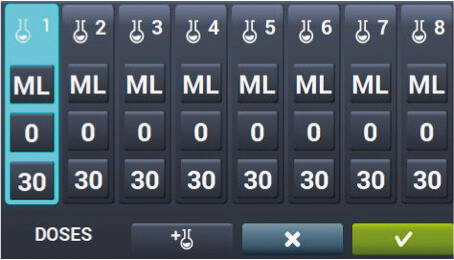

Dosing

Dosing with the necessary amount at the correct time provides you with security during the process and uniformity in the result. And most importantly: your peace of mind. 8 dosage signals as standard + 6 extra signals (time of dosage, start delay, start selection) in all models.

Advertising

The Touch Plus Control screen offers the possibility of an innovative use that increases income prospects for both self-service laundries and individuals: advertising. You can now include information on timetables and prices on the washing machine itself, as well as the service on offer and commercial messages from third parties. All this in an attractive and eye-catching manner.

Large Diameter Door

The Kare generation has been designed with the user’s convenience in mind. To that end, one of the factors indicated in their construction has been to give all the washers the largest door dimensions on the market. This makes loading and unloading much easier and ergonomic, especially in the case of large washers.

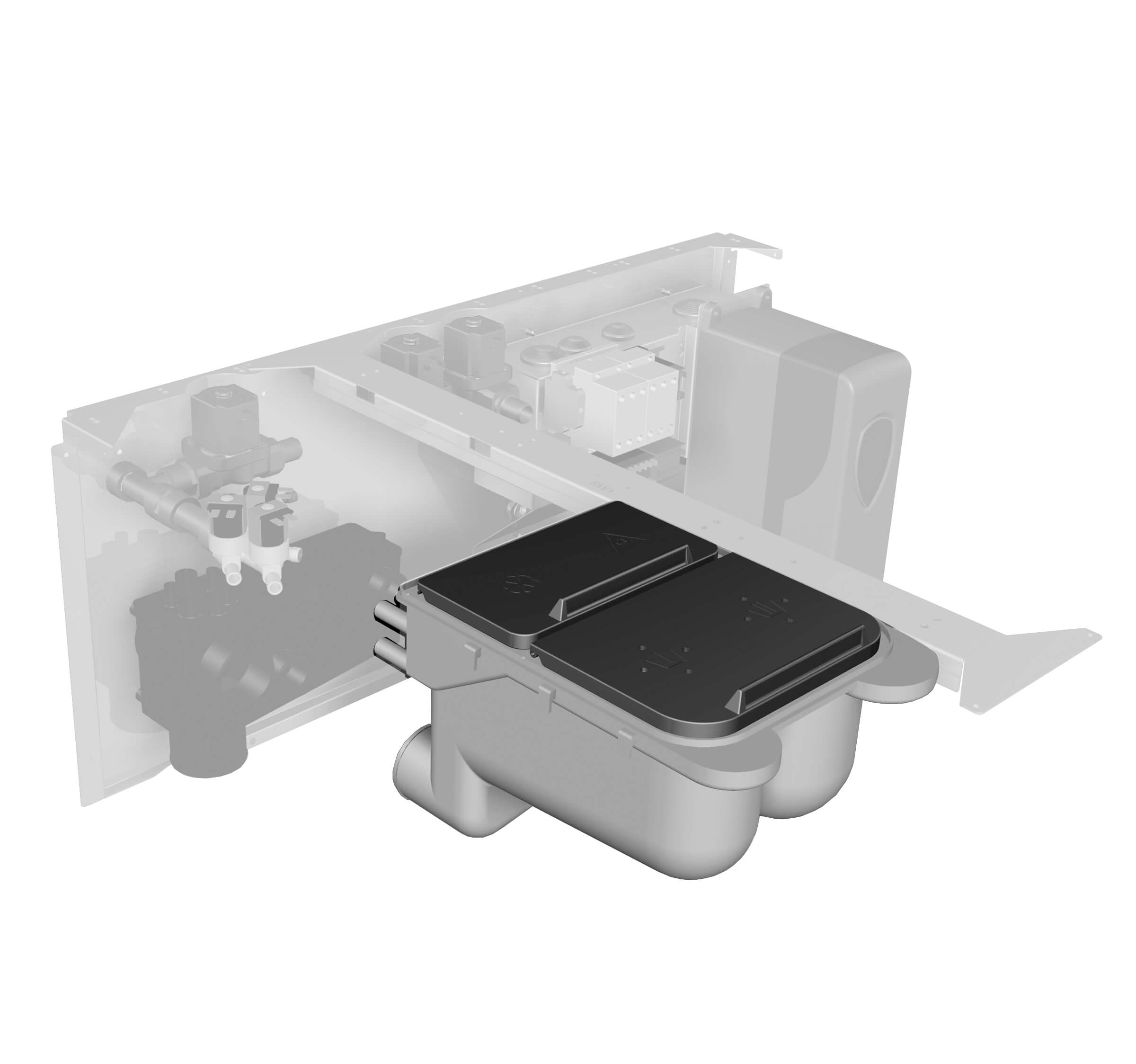

Plinths

Both ergonomics and appearance have been taken into account in the design of the plinths for the LA models:

- The plinths for the 11, 14, 18, 25, 35 and 45kg models have been designed to keep the loading door at the same height in all the models: 850 mm. This solution makes the use of trolleys much easier and more ergonomic.

- Plinths are also available for the same models with a different design to maintain the same height in all the washers, especially conceived for self-service

- Filtering plinths are available for washing mops, for high-spin models of 11,14 and 18 kg, with a drawer opening for cleaning the filter.

Touch Plus – Technical Menu

The Touch Plus Control technical panel allows comprehensive verification of a multitude of functions: the auto-test for faults, alarms, restricted access zones and the storage of relevant information such as cycles, operation time, spin speed, etc.

Kare – Maintenance

The design, simple and robust, has been focused on the correct positioning of each component, and on the lowest possible maintenance. It has been optimised down to the finest detail related to access, including the hinge- opening front panel which provides easy access to the control panel

Wet Cleaning

Fagor Professional offers the most flexible solution on the market to put a Wet Cleaning solution into practice. The machines are versatile, with both washers and dryers providing the possibility of creating different phases by program, including all the personalised parameters required by each detergent supplier in the Wet Cleaning industry. It is a flexible business proposal, given that Fagor Professional has cooperated beforehand with the chemical companies of highest repute in the world, and has tested the programs for specific detergents in advance. As a result, you can continue to cooperate with your detergent supplier and their integration into your Fagor Professional Washers equipment will be instantaneous.

OPL – Self Service

The machines can be changed from OPL (industrial washing) to Self-service and vice versa using the Touch Plus (TP2) control.

Intelligent Weighing System

An system of automatic adjustment carried out by the washer itself which intelligently regulates water and detergent consumption in accordance with the load inserted. Also offers the option of indicating the load weight manually. This reinvests in a considerable saving of energy, water and chemical products.

Optimum Load

Thanks to the advanced technological development of the Kare range, the machine is capable of detecting any kind of imbalance in its functioning ahead of time. In this way, once the anomaly has been corrected, the work is done more gently, which lengthens the life of the components and reduces wash times and energy expenditure

High G-Force

The Fagor washers come with the highest G-force on the market. This brings numerous advantages such as the reduction of water retention in the linen and of drying times. In conclusion, they reduce your operational costs and save energy.

Drum Design

The effective design of the whole Kare washing machine range, based on a series of perforations in the edges of the drum and with minimal spaces between it and the tank, allows only the energy consumption necessary to heat the water to be used, and to reduce the superfluous use of chemical products

Water Cascade

Through a series of perforations in the paddles of the machine, a water cascade effect is achieved which enhances the mechanical action of the drum during operation and considerably reduces the amount of water needed in each wash.